GPPS Acrylik Sheet

GPPS Acrylik Sheet Specification

- Process

- Extrusion

- Material

- GPPS (General Purpose Polystyrene)

- Thickness

- 2 mm 8 mm

- Size

- 1220 mm x 2440 mm

- Length

- 2440 mm

- Light Transmittance %

- 92%

- Grade

- Industrial

- Color

- Transparent

- Surface

- Smooth

- Density

- 1.05 Gram per cubic centimeter(g/cm3)

- Usage

- Advertising, Sign Board, Display, Craft, Light Diffusion

- Recyclability

- Yes

- Tensile Strength

- 60 MPa

- Packing

- Protective film on both sides

- Hardness

- Rockwell R80 R100

- Shape Available

- Sheet

- UV Resistance

- Limited

- Impact Strength

- 2.5 kJ/m

- Flame Retardancy

- No

- Water Absorption

- 0.04%

- Max Working Temperature

- 80C

GPPS Acrylik Sheet Trade Information

- Main Domestic Market

- All India

About GPPS Acrylik Sheet

Exceptional Optical Clarity and Durability

The GPPS acrylic sheet stands out with its high light transmittance of 92%, offering remarkable clarity for display and signage needs. Its resilience is ensured by a tensile strength of at least 60 MPa and impact resistance of 2.5 kJ/m, making it suitable for both indoor and outdoor applications, though UV resistance is limited. These sheets are engineered to deliver dependable performance in demanding environments.

Versatile Applications and Simple Processing

These sheets can be used in advertising, sign boards, light diffusion, and crafts. The smooth surface and industrial grade quality allow for easy processing through extrusion or other fabrication techniques. The standardized size and thickness range enable effortless integration into a variety of projects, while the protective film on both sides ensures the product reaches you in prime condition.

Eco-Conscious Choice and Reliable Supply

The GPPS acrylic sheets are fully recyclable, contributing to sustainable practices in industry and craft. Available from distributors, exporters, manufacturers, service providers, suppliers, and traders throughout India, these sheets are easily accessible for both large-scale and bespoke projects. Their industrial grade makes them the preferred choice for professional use.

FAQs of GPPS Acrylik Sheet:

Q: How are GPPS acrylic sheets typically processed for use in displays and signage?

A: GPPS acrylic sheets are most commonly processed through extrusion and other fabrication techniques such as cutting, drilling, and thermoforming. Their smooth surface and standard sizing allow for easy customization to fit various display and signage requirements.Q: What benefits does the high light transmittance of GPPS acrylic sheets offer for advertising and craft applications?

A: With 92% light transmittance, GPPS acrylic sheets provide exceptional clarity and brightness, making them ideal for advertising displays, illuminated sign boards, and light diffusion panels in creative projects.Q: When should you consider using GPPS acrylic sheets over other plastic sheets?

A: GPPS acrylic sheets are best chosen when you need high transparency, a smooth surface, good mechanical strength, and recyclability for industrial applications such as advertising, signage, and display but do not require strong flame retardancy or advanced UV resistance.Q: Where can GPPS acrylic sheets be sourced in India?

A: They are widely available through authorized distributors, exporters, manufacturers, service providers, suppliers, and traders across India, offering convenient sourcing options for bulk and specialized requirements.Q: What is the recommended maximum working temperature for these sheets and why does it matter?

A: The recommended maximum working temperature is 80C. Staying within this limit ensures that the sheet maintains its structural integrity and prevents warping or deformation during use in industrial and creative applications.Q: How is the recyclability of GPPS acrylic sheets beneficial to users and the environment?

A: Being fully recyclable means GPPS acrylic sheets can be reused or repurposed after their initial lifecycle, reducing waste and supporting environmental sustainability in workshops and commercial settings.Q: What protections are provided during shipping and handling of these sheets?

A: Each GPPS acrylic sheet is packed with a protective film on both sides, safeguarding the surface from scratches, dust, and minor abrasions during transport, handling, and storage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

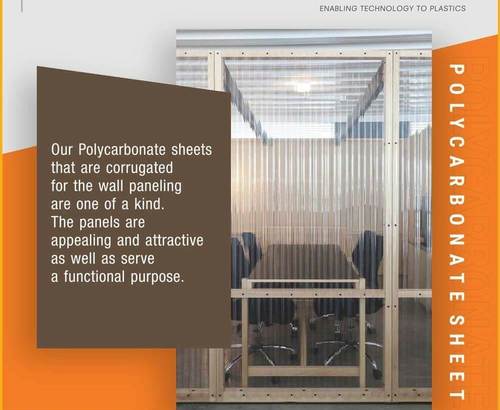

More Products in Acrylic Sheets Category

Polycarbonate Compact Sheet

Thickness : 1.5 mm to 12 mm (Custom sizes available)

Color : Clear, Blue, Green, Bronze, Opal, Custom

Length : Customized, up to 12 meters

Grade : Virgin, Industrial Grade

Light Transmittance % : 80% 92%

Process : Other , Extrusion

Polystyrene Sheet

Thickness : 1 mm to 10 mm

Color : Transparent, White, or as required

Length : Customized or Standard

Grade : General Purpose (GPPS), High Impact (HIPS)

Light Transmittance % : 8590%

Process : Other , Extruded / Molded

Acrylic Light Diffusion Sheet

Thickness : 2 mm 10 mm

Color : White (Milky)

Length : As per requirement

Grade : Premium

Light Transmittance % : 8590%

Process : Other , Cast / Extruded

Acrylic Plastic Sheet

Thickness : 2 mm to 20 mm

Color : Transparent

Length : 2440 mm

Grade : Standard

Light Transmittance % : 92%

Process : Other , Extruded or Cast

"We want foreign inquiries"

Send Inquiry

Send Inquiry