Polystyrene Sheet

Polystyrene Sheet Specification

- Process

- Extruded / Molded

- Material

- Polystyrene (PS)

- Thickness

- 1 mm to 10 mm

- Size

- Standard sizes or custom cut

- Length

- Customized or Standard

- Light Transmittance %

- 85-90%

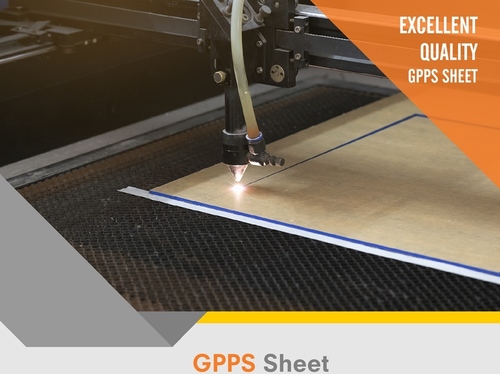

- Grade

- General Purpose (GPPS), High Impact (HIPS)

- Color

- Transparent, White, or as required

- Density

- 1.04 Gram per cubic centimeter(g/cm3)

- Surface

- Glossy, Smooth

- Usage

- Signage, Packaging, Art & Craft, Model Making, Display

- Water Absorption

- <0.1%

- Chemical Resistance

- Good to acids, limited to solvents

- Storage Temperature

- Below 50°C

- Tensile Strength

- 40-60 MPa

- Heat Distortion Temperature

- Around 70°C

- Hardness

- Shore D 70-80

- Recyclability

- Yes, recyclable as code 6

- UV Resistance

- Limited, requires additives for outdoor use

- Flammability

- Combustible

Polystyrene Sheet Trade Information

- Main Domestic Market

- All India

About Polystyrene Sheet

Superior Mechanical and Optical Properties

Polystyrene sheets combine impressive tensile strength (40-60 MPa) with high clarity (85-90% light transmittance), offering both durability and visual appeal for various applications. Their smooth, glossy surfaces suit art, craft, display, and signage projects, while their Shore D hardness ensures adequate resistance to routine wear and tear. This balance makes polystyrene an excellent material for both functional and decorative purposes.

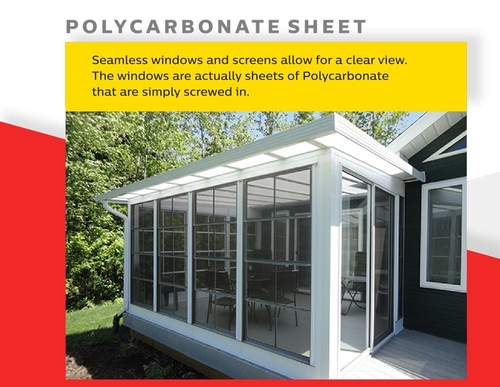

Customizable and Versatile Solutions

Available in thicknesses from 1 mm to 10 mm and multiple standard or custom sizes, polystyrene sheets can be tailored to specific requirements. Choose from transparent, white, or custom-colored options to match project aesthetics. The material can be extruded or molded to achieve different finishes and is suitable for cutting, shaping, and easy handling in manufacturing, educational, and creative settings.

Responsible and Sustainable Material Option

Polystyrene sheets are recyclable (plastic code 6), supporting efforts toward sustainable material use. They offer excellent chemical resistance to acids and moderate resistance to solvents, making them reliable for packaging and storage. While naturally flammable and with limited UV resistance, proper additives can extend their outdoor lifespan. Store below 50C to maintain product integrity.

FAQs of Polystyrene Sheet:

Q: How are polystyrene sheets typically processed for specific uses?

A: Polystyrene sheets are produced through extruding or molding, resulting in smooth, glossy surfaces ideal for further fabrication. They can be easily cut, shaped, engraved, or thermoformed to fit applications like signage, packaging, and model making. These processes cater to both standard and custom requirements.Q: What benefits do polystyrene sheets provide for signage and displays?

A: With high light transmittance (85-90%), a glossy finish, and stable dimensional properties, polystyrene sheets offer excellent visual clarity and impact for signage and display projects. Their ability to be color-customized and shaped enhances their versatility in creative and commercial environments.Q: Can polystyrene sheets be used outdoors, and what precautions are necessary?

A: Polystyrene sheets have limited UV resistance, which means they can yellow or degrade under prolonged sunlight. For outdoor use, it is recommended to incorporate UV additives or treatments to improve stability. Without such treatments, indoor use is preferable to maintain product longevity and appearance.Q: Where are polystyrene sheets commonly applied?

A: These sheets are popular in industries such as signage, packaging, art and craft, model making, and product displays. Their clarity, strength, and ease of fabrication make them a top choice for both industrial and creative applications.Q: What is the best way to store polystyrene sheets?

A: Store polystyrene sheets in a cool, dry environment below 50C to prevent warping or degradation. Avoid exposure to direct sunlight or high heat to maintain their physical and optical properties over time.Q: Are polystyrene sheets environmentally friendly?

A: Polystyrene sheets are recyclable under resin code 6. Responsible disposal and recycling help reduce environmental impacts, and many suppliers provide collection or recycling services to support sustainability practices.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Acrylic Sheets Category

Acrylic Sheet

Length : 1220 mm, 2440 mm or customized

Light Transmittance % : 9293%

Thickness : 1mm to 20mm or custom

Grade : A Grade

Size : 1220 x 2440 mm, 1220 x 1830 mm, Custom sizes

Usage : Signage, Lighting, Display, Decoration, Construction, Crafts

PS Acrylic Sheet

Length : 2440 mm

Light Transmittance % : 92%

Thickness : 2 mm

Grade : Industrial

Size : 1220 x 2440 mm

Usage : Advertising, Sign Board, Decoration

GPPS Acrylik Sheet

Length : 2440 mm

Light Transmittance % : 92%

Thickness : 2 mm 8 mm

Grade : Industrial

Size : 1220 mm x 2440 mm

Usage : Advertising, Sign Board, Display, Craft, Light Diffusion

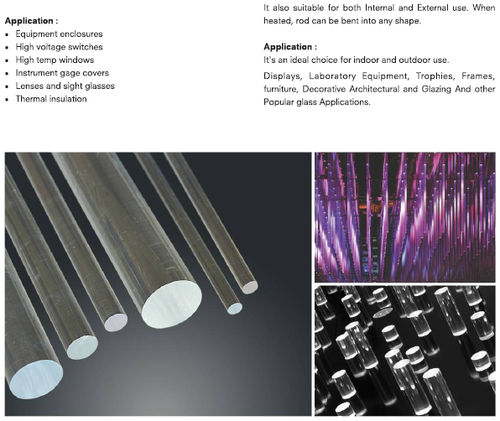

Acrylic Rod & Tube

Length : 1000 mm (Standard), Customizable

Light Transmittance % : 92%

Thickness : 1 mm 50 mm (Rods), 1 mm 10 mm (Tubes)

Grade : General Purpose, Optical Grade

Size : Diameter: 3 mm 200 mm (Rods), Outer Diameter: 3 mm 150 mm (Tubes)

Usage : Signage, Display, DIY Projects, Industrial Applications

"We want foreign inquiries"

Send Inquiry

Send Inquiry