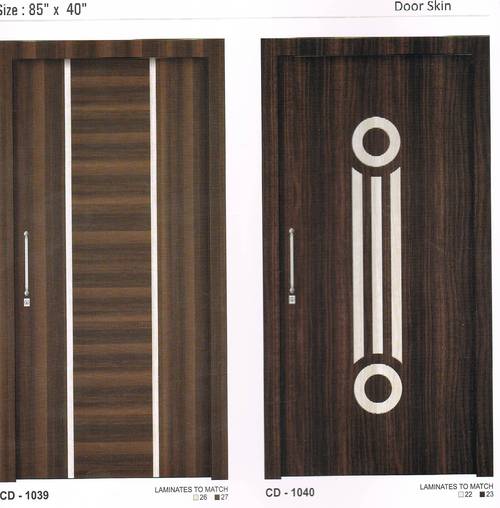

Decorative Laminates Door Skin

Decorative Laminates Door Skin Specification

- Face

- Okoume, Bingtangor, Pencil cedar

- Usage

- construction, Furniture, Door, Flooring, Wall panel, Outdoor, Indoor

- Feature

- Anti Cracking, Environmental Friendly, Strong screw holding, Wear Resistant, Low Formaldehyde Releasing, Anti Acid, Alkaline Resistant

- Core Material

- Birch, Harwood

- Grade

- Third Class, First Class, Second Class

- Material

- Harwood

- Plywood Type

- Door

- Thickness

- 5-10 Millimeter (mm)

- Glue

- E1

Decorative Laminates Door Skin Trade Information

- Minimum Order Quantity

- 3Ton Sheets

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- Sheet

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Australia, Central America, Africa, Middle East, South America, Western Europe, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About Decorative Laminates Door Skin

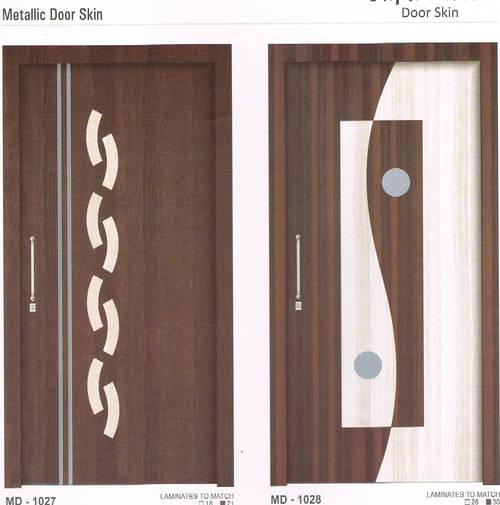

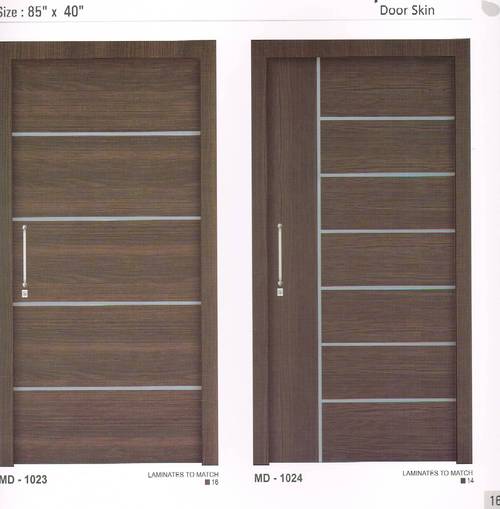

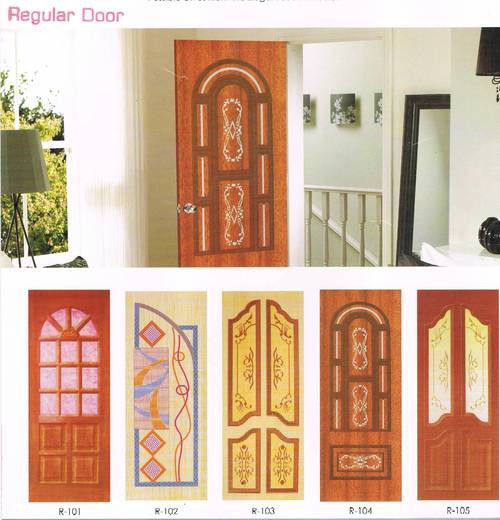

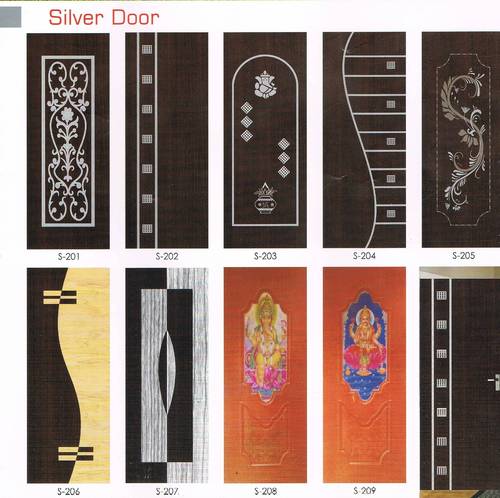

Decorative Laminates Door Skin

We are offering to our clients a wide range of Decorative Laminates Door Skin which are manufactured in compliance with defined quality standards. Our range of elegant Door Skin are available in accordance with clients' specific demands. These Decorative Laminates Door Skin are highly appreciated for features like dimensional accuracy, durable finish standards, wear resistance and longer life.

Versatile Applications Across Industries

Our door skins are engineered for comprehensive use, ranging from indoor and outdoor doors to furniture, flooring, wall panels, and various construction requirements. Their multi-faceted design ensures suitability for both residential and commercial settings, offering flexibility to architects, contractors, and designers alike.

Superior Material Quality

Made with a choice of birch and hardwood core and finished with Okoume, Bingtangor, or Pencil cedar faces, our laminate skins are designed to last. Set in E1-grade adhesive, they present low formaldehyde emissions, ensuring both sturdiness and an environmentally friendly footprint.

Exceptional Performance Features

Enjoy anti-cracking, wear resistance, acid and alkaline protection, and strong screw-holding power. Our decorative laminate skins are tailored to withstand daily use, providing long-term reliability for your construction and design projects.

FAQ's of Decorative Laminateas Door Skin:

Q: How are decorative laminate door skins installed on doors and furniture?

A: The door skin can be affixed to door cores or furniture surfaces using suitable adhesives, and then secured with screws, taking advantage of their strong screw-holding properties. Professional carpentry tools are recommended for precise fitting and finishing during installation.Q: What makes these laminate door skins suitable for both indoor and outdoor use?

A: Our door skins are constructed from hardy birch and hardwood cores with an environmental E1 glue, ensuring resistance to cracking, moisture, acids, and alkalis. This composition offers robust protection and attractiveness in a wide range of environments, both indoors and outdoors.Q: When should one choose First, Second, or Third Class grade for a project?

A: First Class grade is ideal for high-visibility and premium spaces where appearance and durability matter most. Second Class offers a balance between cost and quality, suitable for most general applications, while Third Class is practical for cost-sensitive or less visible construction needs.Q: Where can these decorative laminate door skins be used apart from doors?

A: Beyond doors, these laminate skins are versatile for use in wall panels, flooring, cabinetry, and furniture, enhancing both structural integrity and visual appeal in residential, commercial, and hospitality environments.Q: What is the process behind manufacturing these decorative laminate skins?

A: The process involves selecting high-quality hardwood or birch core materials, applying faces of Okoume, Bingtangor, or Pencil cedar, and bonding them with low-formaldehyde E1 glue. The panels are then pressed, bonded, and finished to provide anti-cracking and wear-resistant surfaces.Q: How does anti-cracking and anti-acid features benefit users in daily usage?

A: These features ensure the surfaces maintain structural and visual quality over time, resisting environmental stresses, chemical exposure, and physical impact, thus extending product lifespan and minimizing maintenance.Q: What environmental advantages does your product offer?

A: With E1-grade low formaldehyde adhesive, renewable wood choices, and recyclable components, our laminate door skins support healthier indoor air quality and promote eco-friendly building practices.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Decorative Door Category

Laminates Door Skin

Minimum Order Quantity : 3Ton Sheets

Face : Bingtangor, Pencil cedar

Material : Harwood

Usage : Indoor, construction, Packing, Door, Flooring, Outdoor

Feature : Moisture Proof, Environmental Friendly, Low Formaldehyde Releasing, Wear Resistant, Anti Acid, Alkaline Resistant

Plywood Type : other, Door

Laminated Door Skin

Minimum Order Quantity : 3Ton Sheets

Face : keruing veneer, Bingtangor, Pencil cedar

Material : Harwood

Usage : construction, Furniture, Decoration, Door, Wall panel, Outdoor, Indoor, Flooring

Feature : Environmental Friendly, Wear Resistant, Anti Acid, Moisture Proof, Strong screw holding, Low Formaldehyde Releasing, Alkaline Resistant

Plywood Type : other, Door

Laminated Flush Door

Minimum Order Quantity : 3Ton Sheets

Face : Bingtangor, Pencil cedar

Material : Harwood

Usage : construction, Decoration, Packing, Outdoor, Indoor, Door

Feature : Anti Cracking, Anti Acid, Environmental Friendly, Moisture Proof, Strong screw holding, Wear Resistant, Low Formaldehyde Releasing, Alkaline Resistant

Plywood Type : other, Door

Laminates Flush Door

Minimum Order Quantity : 3Ton Sheets

Face : Bingtangor, Pencil cedar

Material : Harwood

Usage : Furniture, Decoration, Packing, Door, Flooring, Outdoor, Indoor

Feature : Moisture Proof, Environmental Friendly, Wear Resistant, Anti Acid, Strong screw holding, Anti Cracking, Low Formaldehyde Releasing, Alkaline Resistant

Plywood Type : other, Door

"We want foreign inquiries"

Send Inquiry

Send Inquiry